3 Advanced Toolpath Strategies in Mastercam for Precision Machining

In the competitive world of manufacturing, achieving precision and efficiency is crucial. As machine shops strive to meet growing demands for both speed and quality, the need for advanced software solutions has never been greater. Mastercam is one such tool that enables manufacturers to reach new levels of accuracy and productivity. Let's explore three advanced toolpath strategies in Mastercam that help machine shops minimize waste, increase production, and improve overall machining efficiency.

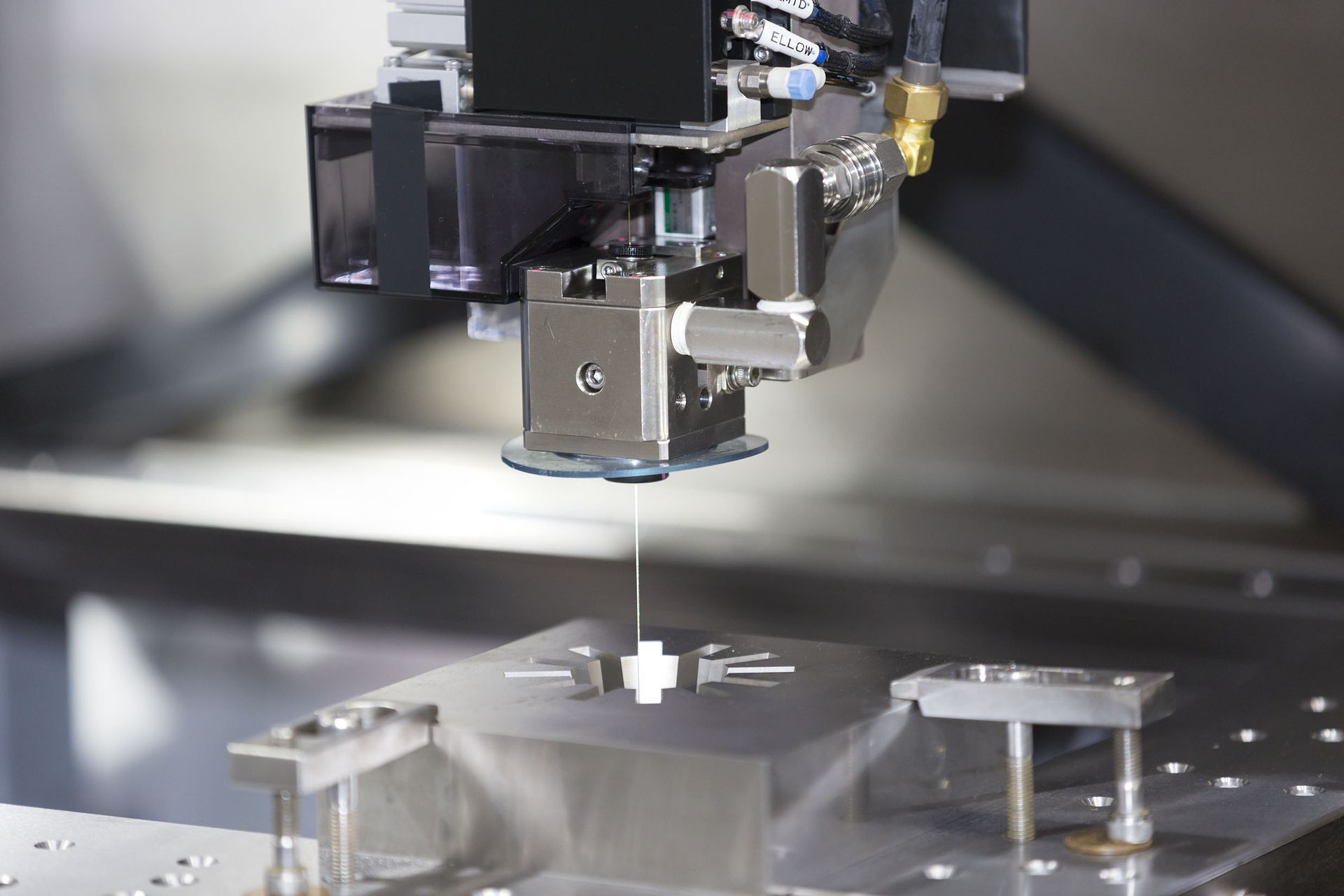

1. Dynamic Milling: Optimizing Tool Engagement for Longevity

One of Mastercam's standout features is dynamic milling. This innovative toolpath strategy focuses on achieving consistent tool engagement, which helps reduce tool wear and optimize cutting conditions. By maintaining an even chip thickness, dynamic milling minimizes heat buildup, which not only extends tool life but also ensures smoother operations. According to IBISWorld, the number of businesses in the manufacturing industry in the United States grew by 1.1% in 2023, and shops are increasingly adopting dynamic milling as part of their strategy to stay competitive. A Mastercam reseller can provide the expertise to fully integrate this toolpath method into your manufacturing process, optimizing productivity and reducing costs in the long run.

2. High-Speed Machining (HSM): Cutting Cycle Times Without Sacrificing Quality

Another powerful toolpath strategy in Mastercam is high-speed machining (HSM). HSM is designed to achieve higher feed rates without compromising the precision or surface finish of the final product. By adjusting spindle speeds and feed rates, HSM helps reduce cycle times, resulting in faster production and smoother finishes. As the manufacturing sector grows, leveraging HSM techniques through Mastercam can help shops stay ahead of the curve. A Mastercam reseller can guide you through the implementation of HSM, ensuring that your machinery operates at peak performance levels.

3. Multiaxis Machining: Achieving Complex Geometries With Precision

When it comes to machining complex parts with intricate geometries, multiaxis machining is a game-changer. Mastercam's multiaxis toolpaths enable manufacturers to handle complicated contours and features with ease. These advanced strategies help reduce the need for multiple setups, streamline production, and improve accessibility to various features. Additionally, multiaxis machining minimizes the risk of human error, which can be costly and time-consuming. As the demand for more sophisticated designs increases, adopting multiaxis machining strategies with Mastercam will allow your business to thrive. A trusted Mastercam reseller can help you implement these cutting-edge techniques, ensuring that your shop can handle even the most demanding projects.

As the industry continues to grow and evolve, leveraging Mastercam's robust solutions will be vital for staying competitive. For more information or to get started with our services, reach out to Sierra Cad/Cam, Inc today!

Share On: